Introduction:

In the world of precision engineering and tooling, the right equipment can make all the difference. That’s where the ACE Spot Drill comes into play, a game-changer in the realm of drilling tools. Designed for professionals who demand accuracy and efficiency, the ACE Spot Drill offers a unique combination of features that set it apart from conventional spot drills.

Unmatched Precision and Versatility:

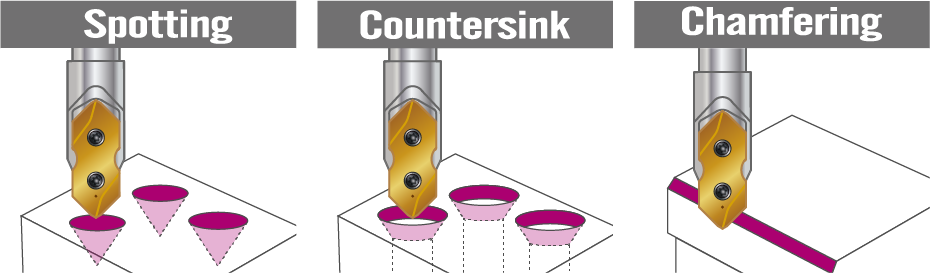

The ACE Spot Drill is available in a range of angles – 60°, 90°, 120°, and 142° – catering all of your spot drilling needs. Whether you’re working on intricate metalwork or robust engineering projects, these drills provide the flexibility to tackle diverse tasks with precision. The versatility of the ACE Spot Drill makes it an indispensable tool in any CNC workshop.

Engineered for Rigidity and Efficiency:

One of the standout features of the ACE Spot Drill is its exceptional rigidity. This is achieved through a dual clamping screw design, which ensures precise positioning of the insert. This design not only reduces vibration during cutting but also enhances the overall stability of the drill. As a result, users experience smoother operation and more accurate drilling, even at high feed rates.

Innovative Design for Enhanced Performance:

The symmetric 2-flute edge design of the ACE Spot Drill plays a crucial role in reducing lateral force. This innovative feature not only contributes to the rigidity of the drill but also allows for higher efficiency in material removal. The reduced lateral force means less strain on the tool and the workpiece, leading to cleaner, more precise cuts.

Durability That Lowers Production Costs:

Durability is a key factor in any tooling equipment, and the ACE Spot Drill excels in this area. The double point angles of the insert tip are designed for increased strength, prolonging the service life of the drill. This extended durability means fewer replacements, reducing production costs over time. It’s an investment that pays off in the long run, both in terms of performance and economics.

Optimal Coolant Design for High-Speed Operations:

The ACE Spot Drill also features an optimal internal coolant design. This innovative aspect ensures better balance and cooling during high-speed operations. This feature is particularly beneficial in high-speed drilling applications, where precision and tool longevity are paramount.

Conclusion:

The ACE Spot Drill is more than just a tool; it’s a testament to innovation and engineering excellence. Its unique combination of precision, versatility, rigidity, and durability makes it a top choice for professionals in the engineering and tooling industry. Whether you’re drilling through metal, plastic, or composite materials, the ACE Spot Drill ensures high-quality results every time. Embrace the future of drilling with the ACE Spot Drill – where precision meets performance.